Table Of Contents

Exploring Propeller Aircraft Engines: Performance and Advantages of Propeller Planes and Aircraft Engines

Key Takeaways

- Summary of aircraft propulsion systems and their significance in aviation.

- Insights into the mechanics and operation of propeller-driven engines.

- Evaluation of performance metrics and efficiency of propeller systems.

- Comparison of turbine propulsion systems and their contribution to flight.

- Advances in propeller technology and their impact on aviation efficiency.

Overview of Aircraft Engines

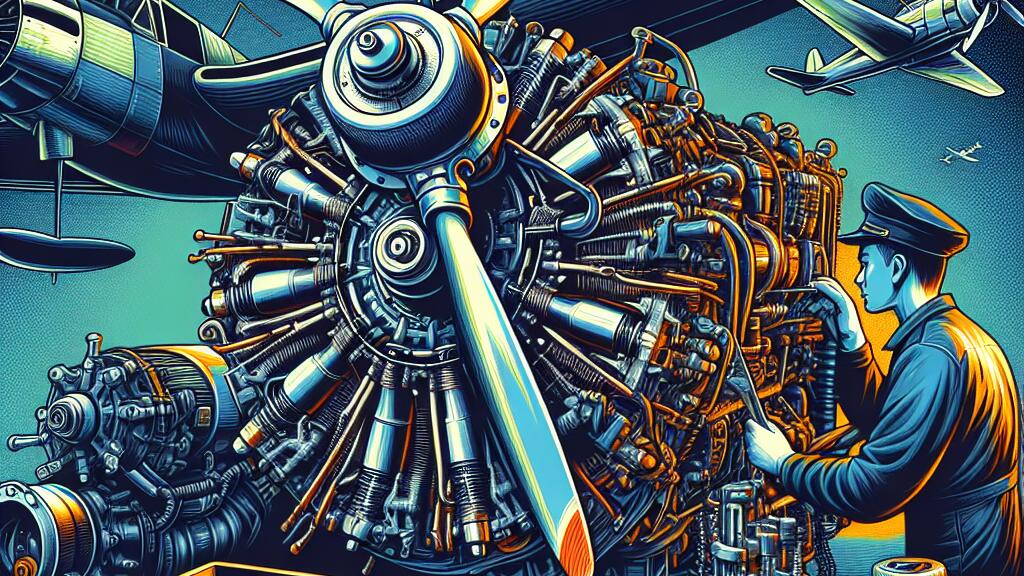

The landscape of aircraft engines is diverse, encompassing a variety of designs that cater to different flight needs. Propeller Aircraft Engines, for example, utilize an aircraft propeller to convert rotational energy from the engine into thrust. This setup is typical in propeller-powered aircraft and propeller-driven aircraft, where efficiency at lower speeds is crucial. Aircraft piston engines are commonly found in smaller general aviation aircraft, playing a vital role in aircraft propulsion. On the other hand, jet engines offer a different method of propulsion, using high-speed exhaust gases to generate thrust for powered aircraft. The design differences between these types of engines, including their respective propeller designs and configurations, influence the performance and operational capabilities of various aircraft. The propeller shaft connects the engine to the propeller, allowing for the effective translation of power into forward motion, highlighting the intricate relationship between these components in the realm of aviation.

Types of Aircraft Engines

Aircraft engines are categorized primarily into two types: propeller aircraft engines and jet engines. Propeller aircraft engines use rotating blades, or propellers, to generate thrust. This category includes fixed-pitch propellers and ducted propellers, often found in general aviation and military aircraft. Aircraft diesel engines, a type of propeller engine, rely on diesel fuel for efficient performance, making them a popular choice for model aircraft and experimental aircraft designs.

Jet engines, on the other hand, are characterized by their reliance on aircraft fuel to create thrust through the expulsion of high-speed jets of air. These engines are commonly used in commercial and military jet aircraft, known for their ability to operate at higher altitudes and speeds compared to propeller engines. The efficiency and power output of these aero engines significantly impact aircraft performance and design, leading to innovations that further enhance flight capabilities.

Comparison between Jet Engines and Propeller Engines

Jet engines and propeller aircraft engines serve different purposes and capabilities in aviation. Turbojet aircraft rely on jet turbine technology to produce thrust, making them ideal for high-speed applications. Business aircraft often utilize turbine engines for their efficiency at higher altitudes and speeds compared to piston-driven aircraft. On the other hand, propeller aircraft engines, including those equipped with constant-speed propellers, excel in lower-speed environments and short-distance travel. These engines generally yield better fuel efficiency for small airplanes, particularly in general aviation and regional flights.

Aircraft designers consider the unique advantages of each engine type depending on the mission profile. Fighter aircraft frequently adopt turbojet engines to achieve supersonic speeds, while electric aircraft are now emerging, showcasing innovations in propulsion technology. Propeller aircraft engines remain a popular choice for training and recreational flying, offering simplicity and operational cost-effectiveness. The ongoing development of advanced propeller designs aims to minimize issues such as propeller strike, further enhancing their viability in modern aviation.

Understanding Propeller Aircraft Engines

Propeller Aircraft Engines play a crucial role in the aviation industry, particularly for general aviation aircraft and smaller passenger aircraft. These engines utilize a propeller driven by a piston or turbine engine to create thrust, differing significantly from jet propulsion systems. A common design feature in modern propeller engines is the constant speed propeller, which optimizes performance and efficiency across various flight conditions. Companies like Safran Aircraft Engines are at the forefront of innovation in aircraft propeller design, developing advanced aero-engines that enhance the overall capabilities of propeller planes. This innovation allows for improved performance and fuel efficiency, making propeller aircraft a popular choice for regional travel and specialized applications.

Components of Propeller Aircraft Engines

Propeller Aircraft Engines are composed of several critical components that contribute to their overall functionality and efficiency. Key elements include the attached propeller, which is designed based on propeller characteristics such as size, shape, and pitch. Different propeller types serve distinct roles in propeller propulsion. The design and functionality of modern propellers are influenced by aircraft engine theory, which helps maximize propeller performance and efficiency. The propeller-control system is vital for regulating the operation and ensuring optimal thrust during various flight stages.

The efficiency of Propeller Aircraft Engines significantly depends on the integration of advanced propeller technology. Each propeller must be meticulously engineered to enhance propeller performance, especially in specialized applications like military aircraft engines. The interaction between the engine and the airplane propellers plays a crucial role in delivering the power necessary for flight. As propeller technology continues to evolve, innovations aim to improve overall propeller efficiency while addressing the demands of modern aviation.

Advantages of Propeller Aircraft Engines

Propeller Aircraft Engines offer significant advantages in terms of performance and efficiency, especially in light aircraft engines. The design of these engines allows for high levels of propeller efficiency, particularly with well-optimized propeller blades and tips. Aircraft engine efficiency is enhanced by the reciprocating engine propeller setup, which converts the engine’s power into thrust effectively. Unlike turbine engines, the simplicity of a piston aircraft engine contributes to its reliability, making it an ideal choice for general aviation. This reliability is crucial in scenarios where propeller stops or non-functioning propeller failures could jeopardize flight safety.

The versatility of Propeller Aircraft Engines is evident in their application within electric aircraft engine systems. Electric engine aircraft benefit from the lightweight, efficient design of propeller systems, which can enhance associated propeller performance. The stationary propeller configuration maximizes thrust output while minimizing drag. In many cases, the improved efficiency of these engines translates into longer flight durations and reduced operational costs for pilots and operators alike. The advancements in technology continue to push the boundaries of what can be achieved in propeller performance, leading to exciting developments in aviation.

- Propeller engines generally have lower fuel consumption compared to turbine engines, leading to cost savings.

- They provide better performance at lower altitudes, making them ideal for short flights and regional travel.

- Maintenance and repair costs tend to be lower, as piston engines have simpler mechanical systems.

- Propeller Aircraft Engines can offer superior climb rates, enhancing the ability to take off quickly.

- The noise levels are often more manageable compared to turbine engines, contributing to a quieter flying experience.

- They typically have shorter takeoff and landing distances, allowing access to smaller airstrips.

- The ability to use alternative fuels in some propeller engines promotes environmentally friendly flying options.

Propeller Performance

The effectiveness of Propeller Aircraft Engines hinges on various performance factors. Modern propeller designs have evolved from traditional propellers to optimize propeller thrust, enhancing efficiency in the aircraft propulsion system. Operating propellers in multi-engine aircraft, particularly four-engine aircraft, requires precise management through a propeller control lever that adjusts the pitch of the propeller blade for optimal performance. The propeller diameter plays a crucial role in determining the amount of air the propeller can scoop, directly impacting thrust generation. While turbine jet engines dominate the high-speed aviation sector, propeller engines remain essential in piston-engine airplanes, where they excel in low-speed and low-altitude operations. By understanding these dynamics, engineers can maximize the performance of propeller systems in various aviation applications.

Factors Affecting Propeller Performance

The performance of Propeller Aircraft Engines hinges on several critical factors that can be represented in a propeller performance chart. One major aspect is the propeller tip speed, which influences the efficiency and thrust produced. Higher tip speeds can improve propeller-produced thrust, especially in applications involving twin-engine airplanes or powered model airplanes. Understanding propeller performance curves allows engineers to analyze how small aircraft can achieve optimal speed and fuel efficiency with various driving propellers, thereby enhancing overall performance across the aircraft industry.

Another significant factor is the propeller-control requirements that dictate how effectively the propulsion engines can respond to flight conditions. Engine performance can vary with changes in air density, altitude, and temperature, impacting the propeller’s effectiveness. Composite propeller blades, for example, provide a lightweight and durable alternative that optimizes thrust for jet turbine planes and many propellers used in modern aviation. These elements contribute to the intricate balance of power and control necessary for maximizing propeller performance in diverse flight applications.

Calculating Propeller Efficiency

The calculation of propeller efficiency is essential for optimizing the performance of Propeller Aircraft Engines. Different propellers, including early propellers and modern designs, are tested against various factors such as diameter propellers and propeller pitch. These factors significantly influence the thrust generated and, ultimately, the overall aircraft performance. Successful aircraft, including famous aircraft piston models and private aircraft, often rely on precise calculations to ensure that they operate efficiently.

Understanding the specific aircraft types and their requirements also plays a crucial role in calculating propeller efficiency. Twin-rotor aero engines and aircraft turboprop engines exemplify how varying configurations and designs can affect thrust and speed. By analyzing the relationship between propeller size and engine output, engineers can fine-tune each propulsion system to maximize performance and ensure that the aircraft can fly forwards effectively.

Turbine Engines and Their Role in Aviation

The evolution of turbine engines has greatly impacted modern aircraft design, differentiating them from traditional Propeller Aircraft Engines. Unlike powerful piston aircraft that utilize wooden propellers, aircraft gas turbines streamline propulsion and enhance performance across various aircraft applications. Early innovations, such as the gnome-engined aircraft, laid the groundwork for the development of advanced systems including modern piston aero-engines. The transition to designs featuring five-bladed propellers has improved efficiency and helped drive propellers more effectively. Understanding the propeller blade section and its aerodynamics continues to be crucial as aviation embraces innovative technologies, allowing for faster aircraft speeds and practical improvements in aircraft operation.

Differences Between Turbine Engines and Propeller Engines

Turbine engines and propeller aircraft engines serve distinct roles within aviation. Early aircraft primarily relied on propeller systems, which include small engines that efficiently power general aviation airplanes and small commuter aircraft. These engines leverage the mechanical energy from the rotating propeller to generate thrust. Conversely, jet engines utilize high-speed exhaust jets, providing significant thrust for military aircraft designs and larger commercial aircraft. The difference in propulsion methods greatly influences aircraft performance and application.

Jet engines are often favored for their ability to maintain high speeds over long distances, which is essential for national business aircraft and private airplanes. Propeller aircraft engines, on the other hand, excel in operational cost efficiency and low-speed handling, making them ideal for conventional light aircraft and turboprop-powered aircraft. A few aircraft, particularly small subsonic aircraft, may use either type of engine, but the choice usually depends on the specific jet engine specifications and desired operational characteristics.

Applications of Turbine Engines in Aircraft

Turbine engines have become integral in various aircraft applications over the years, significantly enhancing performance across categories. High-performance aircraft, including rocket-propelled combat aircraft, often rely on these engines to achieve superior thrust and speed. While turboprop-powered aircraft serve moderate-performance roles by combining turbine efficiency with propeller mechanics, lower-performance variants like the single-engine Cessna still benefit from turbine technology. The versatility of turbine engines allows for their use in both civil aircraft and innovative compact aircraft solutions.

Various types of turbine engines power a range of passenger configurations, including seat passenger aircraft. The first jet aircraft showcased the capabilities of turbine technology, establishing a precedent for future designs. Regular jet engines dominate the market for high-speed air travel, while low-speed aircraft utilize turboprop engines for their fuel efficiency. Understanding how a turbine engine works is essential for optimizing performance in higher-performance aircraft. This understanding also extends to ensuring that the design caters to specific operational needs within the aviation industry.

- Turbine engines allow aircraft to achieve faster takeoff and climb rates.

- Their efficient fuel consumption leads to lower operating costs for airlines.

- Turbine engines facilitate long-haul flights by providing the necessary thrust over extended distances.

- They enable quieter operations, reducing noise pollution around airports.

- Jet engines are essential for military aircraft, contributing to higher maneuverability and speed in combat situations.

- The adaptability of turbine engines supports a wide variety of aircraft designs, from commercial jets to small UAVs.

- Continuous advancements in turbine technology are helping to increase overall safety and reliability in aviation.

Innovations in Propeller Technology

Recent advancements in propeller technology have significantly enhanced the performance and efficiency of Propeller Aircraft Engines. Civil aircraft designers are now incorporating innovative designs that improve aerodynamics and reduce noise levels, contributing to a more enjoyable flying experience. For instance, new airplane models often utilize advanced materials and rotary engine designs, allowing for better weight distribution and fuel efficiency. The evolution from the first engines used in WWII airplanes to modern turboprop aircraft showcases a remarkable leap in design and functionality. Enhanced features like fuselage-mounted jets and single-rotor engines are being explored to accommodate the growing demand for ramjet-powered aircraft flight, reflecting the industry’s commitment to pushing technological boundaries while maintaining reliability.

| Innovation | Description | Benefits |

|---|---|---|

| Advanced Composite Materials | Use of lightweight materials such as carbon fiber and composites for propeller blades. | Improved fuel efficiency and reduced weight leading to enhanced performance. |

| Blade Shape Optimization | Enhanced designs that improve aerodynamics through varying blade shapes. | Reduction in drag and noise levels, resulting in a smoother flight experience. |

| Noise Reduction Technologies | Implementation of designs aimed at minimizing sound emissions from propellers. | Quieter operations, contributing to reduced impact on communities around airports. |

| Smart Propeller Systems | Integration of sensors and data analytics to monitor propeller performance in real-time. | Enhanced maintenance and operational efficiency through predictive analytics. |

Recent Advancements in Propeller Designs

Innovations in propeller designs have significantly influenced the development and efficiency of Propeller Aircraft Engines. Recent aviation technology has led to the adoption of coaxial propellers, which allow for more effective piston engines and enhance overall performance. These advancements cater to higher-powered engines, ensuring that the power generated by the piston engine powerplant is utilized more efficiently. This was especially evident in the design evolution seen in the first turboprop aircraft, showcasing how airplane changes can lead to improved operational capabilities.

The integration of modern materials and improved aerodynamics has contributed to the overall performance of common engines in aviation applications. For instance, advancements in shaft engines have resulted in better fuel efficiency and reduced noise levels. The upgrades in propeller designs also play a vital role in enhancing the capabilities of ersatz fighter aircraft, which rely heavily on their propeller-driven dynamics. As aircraft increases in operational demands, these design improvements ensure that Propeller Aircraft Engines remain relevant in an evolving industry.

Conclusion

Propeller Aircraft Engines have played a pivotal role in aviation history, particularly in pre-1950 airplanes, where they were the dominant form of propulsion. These engines are known for their efficiency and effectiveness in generating thrust, supporting the gradual aircraft speed increases that have been essential for modern flight. The design and functionality of Propeller Aircraft Engines allow them to harness power directly from their own engine shaft, making them simpler and more reliable compared to other propulsion systems. Notably, supercharger-equipped aircraft have leveraged this technology to enhance performance at higher altitudes, showcasing the enduring relevance of propeller-driven design in the evolution of aviation.

FAQS

How do propeller driven aircraft differ from turbine aero engines in terms of efficiency and operation?

Propeller driven aircraft typically rely on a propeller operation that is highly efficient at lower speeds, making them suitable for moderate-performance aircraft like the single-engine Cessna. Unlike turbine aero engines, which are more powerful and designed for higher speeds, the efficiency of piston engines in propeller driven aircraft depends on factors such as the design of propeller tips and how effectively they scoop air to generate thrust. While piston engines, such as Thielert aircraft engines, allow for practical aircraft diesel applications, rocket-propelled aircraft and turboprop-powered aircraft provide different operational characteristics suited for specific aviation needs.

How do propeller aircraft engines compare to turboprop-powered aircraft in terms of their efficiency and performance during flight?

In aviation, propeller aircraft engines, including low speed aircraft like the single-engine Cessna, tend to be more efficient than turboprop-powered aircraft at lower speeds. These engines can effectively scoop air and propel the aircraft forwards, making them an ideal choice for lower-performance aircraft. The first aircraft flight featuring practical rotary engines demonstrated the efficiency of piston engines in comparison to modern aviation engines, highlighting the evolution of design and efficiency in propeller depend systems.

What are the advantages of using a propeller efficient engine in a single-engine Cessna compared to a turboprop-powered aircraft regarding aeroplane operation?

In aviation, a single-engine Cessna equipped with a propeller efficient engine typically demonstrates better efficiency than turboprop-powered aircraft when cruising at lower altitudes. Such engines, particularly inline engines, can efficiently scoop air and provide optimal performance, especially in smaller aircraft. This results in overall lower operational costs for piston engines compared to their turboprop counterparts, particularly when flying shorter distances.

How is the efficiency of a single-engine Cessna with a propeller scoop air compared to a turboprop-powered aircraft during flight in terms of the aviation inline engine performance?

In aviation, the efficiency of piston engines in a single-engine Cessna, which uses a propeller scoop air, typically offers different performance characteristics compared to how a turboprop-powered aircraft flies. Piston engines generally provide better efficiency at lower altitudes and slower speeds, while turboprop engines excel in higher speeds and altitudes, offering advantages in longer flights.

How do efficiency piston engines in a single-engine Cessna affect its aeroplane performance during flight compared to other propulsion systems in aviation?

Efficiency piston engines in a single-engine Cessna enhance the aeroplane’s overall performance significantly, offering advantages such as better fuel economy and lower operating costs compared to turbine engines, while providing reliable power for typical aviation inline engine applications.

What features make a single-engine Cessna an optimal choice for pilots seeking efficiency in their flight operations?

A single-engine Cessna is often preferred by pilots due to its simplicity, reliability, and cost-effectiveness. Its design allows for easier maintenance and lower operating costs compared to more complex aircraft. Additionally, the efficiency of the single-engine Cessna contributes to its performance, making it suitable for both training and recreational flying, appealing to new and experienced pilots alike.

What role does the single-engine Cessna play in the training of novice pilots regarding basic flight operations?

The single-engine Cessna is often chosen as a training aircraft for novice pilots due to its simplicity, reliability, and ease of handling, allowing new aviators to develop essential flying skills in a safe environment.

What is the role of single-engine Cessna aircraft in pilot training programs and how do they contribute to the overall learning experience?

Single-engine Cessna aircraft play a crucial role in pilot training programs as they provide a stable and manageable platform for novice pilots. The features of a single-engine Cessna enable students to grasp fundamental flight operations, critical maneuvers, and navigation skills, making it an ideal choice for those pursuing a career in aviation.

What are the critical considerations for choosing a single-engine Cessna as a training aircraft for novice pilots?

When selecting a training aircraft, many flight schools prefer the single-engine Cessna due to its reliability, ease of handling, and affordability. It offers a stable flying experience that is essential for novice pilots to develop their basic flight operations skills effectively. The single-engine Cessna is specifically designed to cater to the needs of beginner pilots, making it an optimal choice for comprehensive pilot training.

What types of operations benefit the most from using a single-engine Cessna in flight training?

The single-engine Cessna is particularly beneficial for flight training operations that prioritize hands-on experience, ease of handling, and cost-effectiveness. Its straightforward design allows novice pilots to develop essential flying skills while gaining familiarity with aircraft systems in a manageable environment, ultimately enhancing their proficiency as they progress in their pilot training.